AJ Tensile is seeking practical self employed sub-contractors to assist us with the installation of various projects (predominantly biogas membranes) throughout the UK.

CSCS accreditation is a must, along with a hands-on and flexible approach.

Please email gary@ajtensile.co.uk expressing your interest.

Date posted: 8 March 2018

Posted in:

Manufacturing, Tension Structures

Keep the snow off the entrance to your building with a canopy by A J Tensile Tension Structures Ltd.

Date posted: 15 January 2018

Posted in:

Tensile Fabrications, Tension Structures

AJ Tensile Tension Systems Ltd was selected by main contractor BAM Construction to provide feature canopies to the walkway at the University of the West of England’s new Enterprise Zone in Bristol. The project consisted of the engineering, manufacture, supply and installation of five bespoke inclined triangular sail canopies to cover the walkway leading up to the Enterprise Zone’s main entrance. AJTTS’s sister company AJ Tensile Manufacturing Ltd fabricated the sails for the project.

This was AJ Tensile Tension Structures’ first project in partnership with BAM Construction, and was successfully completed on time and within budget.

Date posted: 15 January 2018

Posted in:

Tensile Fabrications, Tension Structures

Following the successful completion of two previous cycle shelter canopies on the same Bay Campus development, AJ Tensile Tension Structures Ltd was awarded the contract for the third phase of redevelopment at Swansea University by main contractor Vinci Construction. This phase of the project consisted of the engineering, manufacture, supply and installation of two 8m x 6m double conic tensile fabric canopies from our standard range of products, complete with 28 stainless steel cycle stands. Fabrication of the tensile fabric was performed by sister company AJ Tensile Manufacturing Ltd.

Each canopy was installed over a three day period by three men, with a gap of five weeks between them to fit in with the overall site construction programme. The project was completed successfully on time and within budget.

BAM Construction approached out Tension Structures division to engineer, manufacture and install a feature entrance canopy to a brand new building at Ladysmith School in Exeter, Devon. The bespoke design includes tensile fabric attached to an L-shaped corner gutter to allow rainwater drainage, with an inclined and tapered cantilever column to provide the principle tensioning point of the canopy.

Completed in March 2017, the installation was completed over three days by two men, with the whole project delivered on time and to the agreed budget.

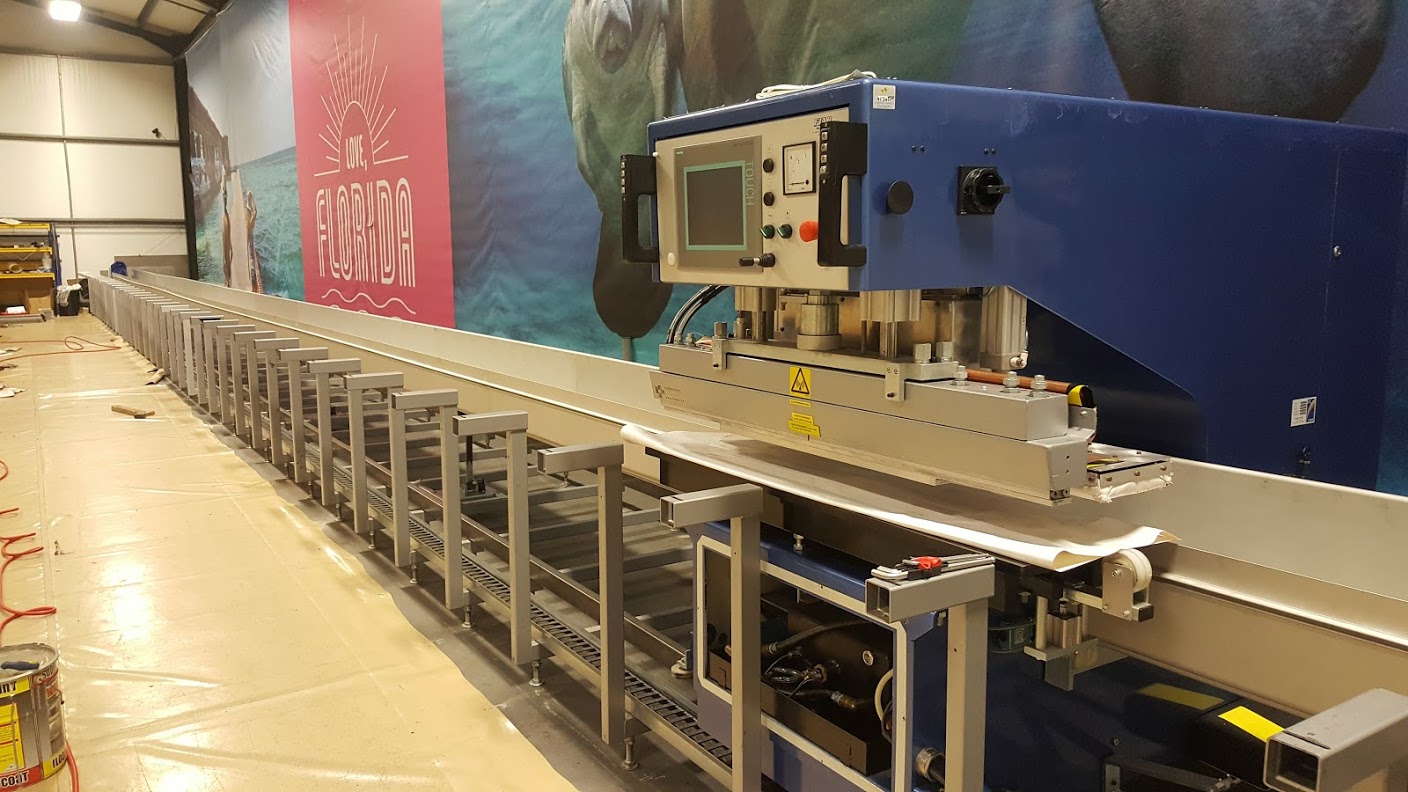

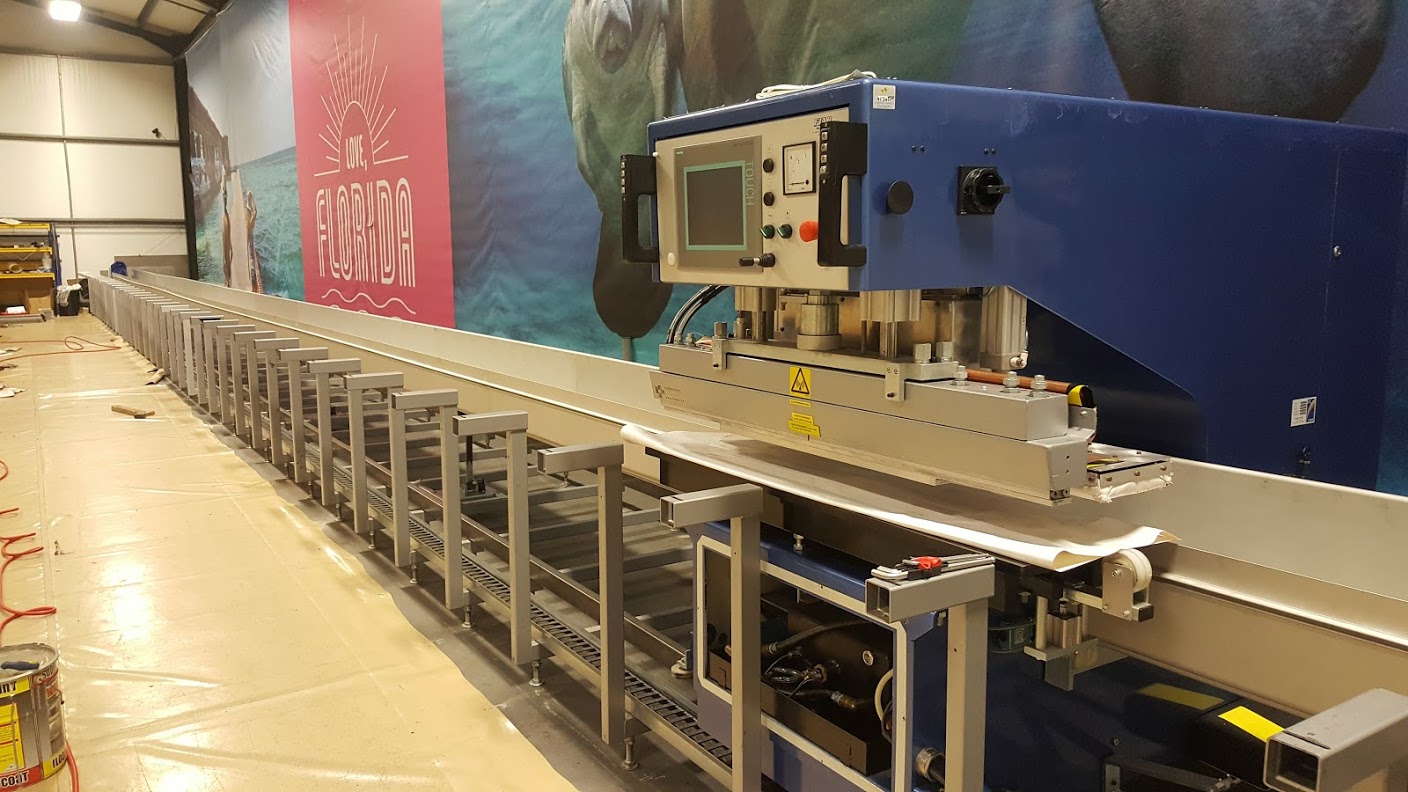

As part of our strategy to cope with ever-increasing production demand, AJ Tensile Group recently upgraded our Manufacturing division’s 12kW Forsstrom HF welding machine to a 17kW FIAB 900. Part of the improvements involved mounting the FIAB to a 28m table, more than double the length of the Forsstrom’s old one.

Out with the old Forsstrom…

…and in with the new FIAB.

In order to bring a better focus on its key markets and improve the high levels of service it already delivers to its customers, AJ Tensile Fabrications Limited has been divided into AJ Tensile Biogas Systems Limited, AJ Tensile Tension Structures Limited, and AJ Tensile Manufacturing Limited. These three companies all operate under the AJ Tensile Group Limited parent company umbrella.

The Biogas and Structures companies will benefit from dedicated staff with an expertise in delivering high quality projects, and will allow the skilled and experienced manufacturing staff to continue to concentrate on producing top quality products.

Biogas Systems will be headed up by Richard Cherry, one of the world’s most experienced and respected experts on anaerobic digestion and biogas storage. The Structures company will be headed up by Gary Patterson who has extensive experience of designing, project managing and installing tensile fabric structures throughout the world. Andrew Jerrum formed AJ Tensile Fabrications Ltd in 2000 and is an expert innovator of industrial fabric manufacture processes. He will head up the manufacturing operation while continuing his role of Group Managing Director.

Andrew said “the business has grown rapidly over recent years and it is increasingly evident that our staff need to become more specialised in order to continue delivering the excellent levels of products and service that our proud reputation is based on. The whole group is dedicated to making the transition as seamless as possible for all staff, customers, and suppliers”.

This website will shortly be updated to reflect these changes.

Date posted: 29 September 2015

Posted in:

Tension Structures

Our Tension Structures division recently completed the installation of this tensile fabric cycle shelter canopy for Vinci Construction on the Science and Innovation Campus at Swansea University. Our team worked closely with Vinci to develop the final design, adapting one of our existing 18m x 8m triple conics to provide a more balanced aesthetic while reducing overall costs. All design, engineering, manufacture and installation of the steel support frame and was undertaken by ourselves in conjunction with our technical partners, and the fabric canopy was manufactured in-house at our Caldicot production facility. The programme from appointment to handover of the finished canopy was around four months.

Date posted: 16 April 2015

Posted in:

Tensile Fabrications, Tension Structures