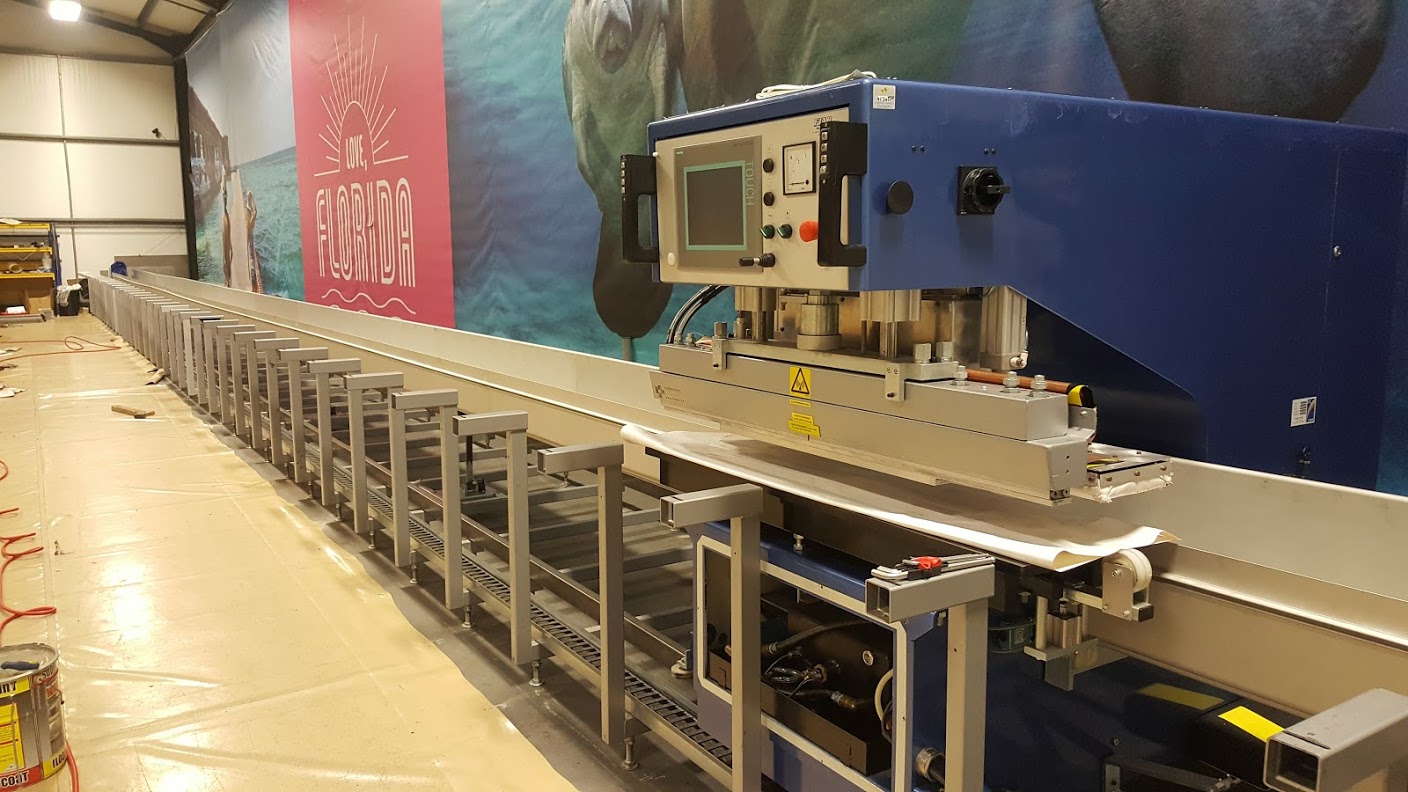

As part of our strategy to cope with ever-increasing production demand, AJ Tensile Group recently upgraded our Manufacturing division’s 12kW Forsstrom HF welding machine to a 17kW FIAB 900. Part of the improvements involved mounting the FIAB to a 28m table, more than double the length of the Forsstrom’s old one.

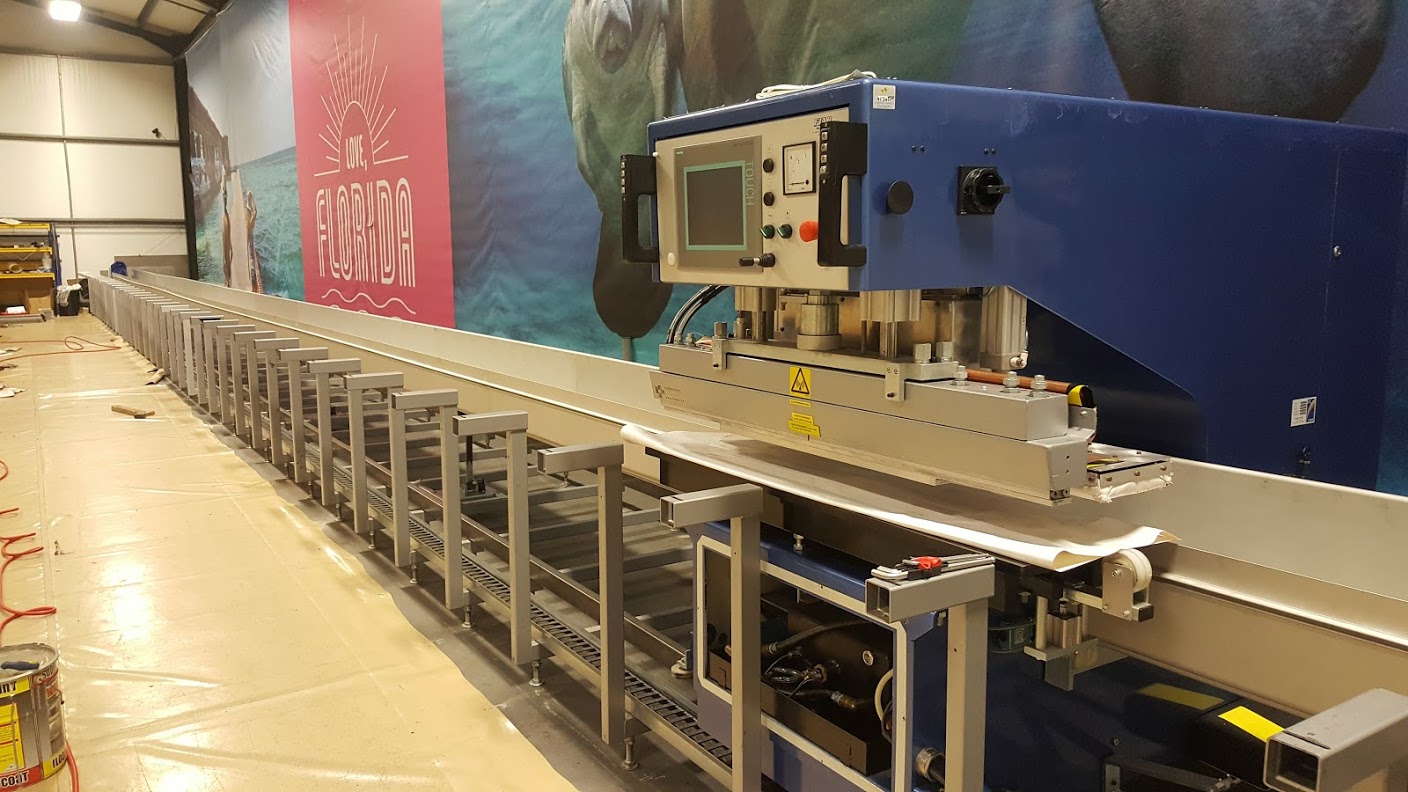

Out with the old Forsstrom…

…and in with the new FIAB.

Date posted: 4 November 2016

Posted in:

Biogas Systems, Tensile Fabrications

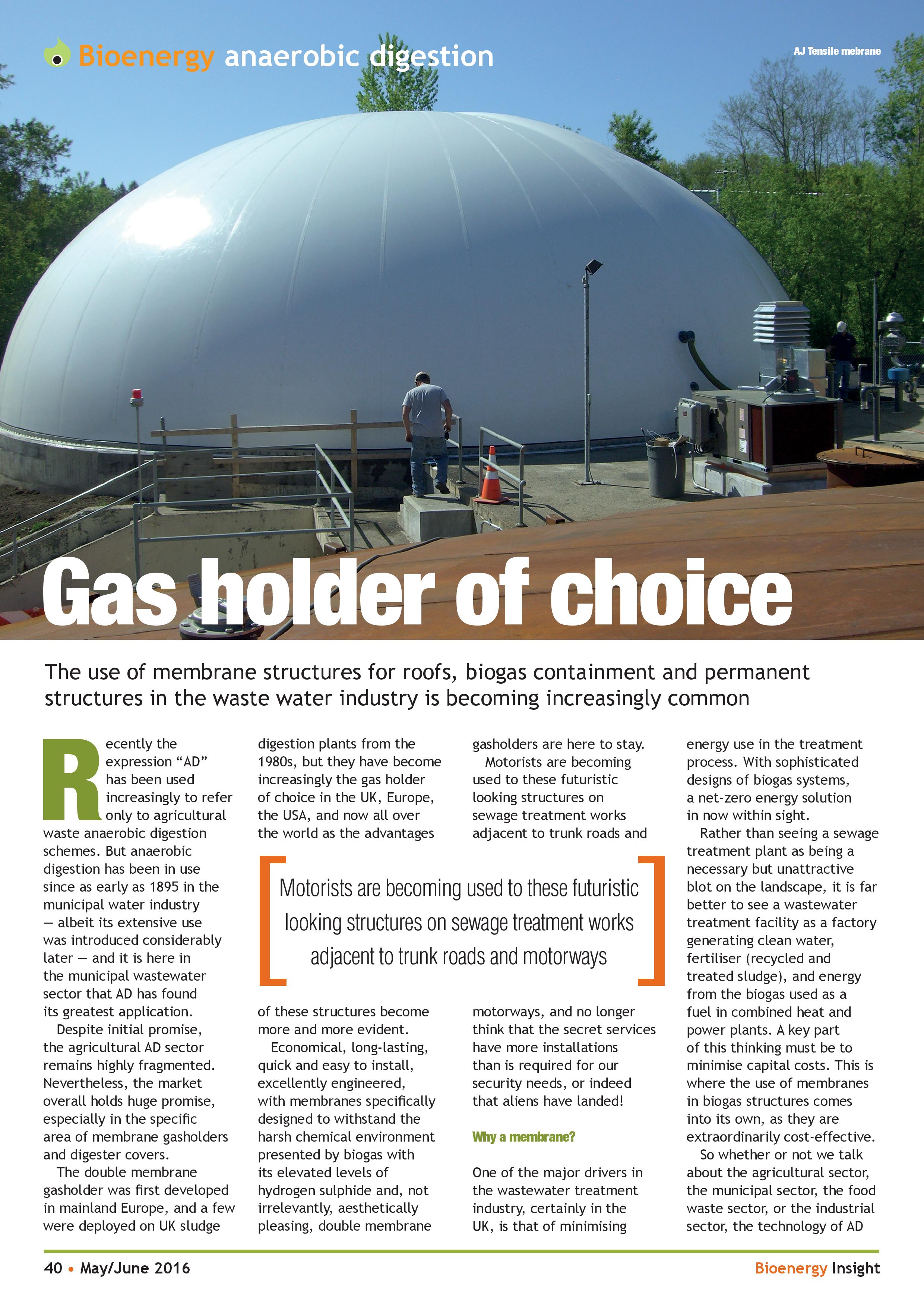

Our Biogas division recently completed this 5,398 cubic metre tank top gasholder for WesTech in the USA. Installed at Waukesha Waste Water Treatment Plant in Wisconsin, the 28m diameter 14m high dome operates at 27 millibar working pressure. The design uses our unique double-membrane construction technique, with the special tan colour of the outer membrane specially requested by the client.

In order to bring a better focus on its key markets and improve the high levels of service it already delivers to its customers, AJ Tensile Fabrications Limited has been divided into AJ Tensile Biogas Systems Limited, AJ Tensile Tension Structures Limited, and AJ Tensile Manufacturing Limited. These three companies all operate under the AJ Tensile Group Limited parent company umbrella.

The Biogas and Structures companies will benefit from dedicated staff with an expertise in delivering high quality projects, and will allow the skilled and experienced manufacturing staff to continue to concentrate on producing top quality products.

Biogas Systems will be headed up by Richard Cherry, one of the world’s most experienced and respected experts on anaerobic digestion and biogas storage. The Structures company will be headed up by Gary Patterson who has extensive experience of designing, project managing and installing tensile fabric structures throughout the world. Andrew Jerrum formed AJ Tensile Fabrications Ltd in 2000 and is an expert innovator of industrial fabric manufacture processes. He will head up the manufacturing operation while continuing his role of Group Managing Director.

Andrew said “the business has grown rapidly over recent years and it is increasingly evident that our staff need to become more specialised in order to continue delivering the excellent levels of products and service that our proud reputation is based on. The whole group is dedicated to making the transition as seamless as possible for all staff, customers, and suppliers”.

This website will shortly be updated to reflect these changes.

A very insightful article was recently published in Black & Veatch’s Solutions Online regarding net-zero energy production at wastewater facilities. We at AJ Tensile Fabrications manufactured the two large biogas domes at United Utilities’ flagship site at Davyhulme, Greater Manchester (shown in the main photo), with senior members of our Biogas division responsible for the design and engineering.

http://bv.com/Home/news/solutions/water/net-zero-energy-in-grasp-of-wastewater-treatment-facilities

Net-Zero Energy Is Now ‘In the Grasp’ of Wastewater Treatment Facilities

It is commonly known that wastewater possesses more energy than needed to operate a treatment facility, but the number of net-zero energy water resource recovery facilities (WRRFs) is still very low worldwide. Yet, a recent study states that the possibility of net-zero energy is now in the grasp of many wastewater facilities, and the report provides some of the best insights on record as to how to achieve such results.

The study, commissioned by the Water Environment Research Foundation (WERF), identifies approaches to reduce energy use and maximize energy production in water resource recovery facilities. The goal is to demonstrate ways wastewater treatment facilities can operate solely on the energy from the water and wastes they treat.

Stephen Tarallo, a Client Services Director for Black & Veatch’s water business, served as co-principal investigator for the project, which is titled “Net-Zero Energy Solutions For Water Resource Recovery Facilities”(ENER1C12).

“The research offers guidance for selecting the combination of technologies and energy management best practices to most effectively achieve energy neutrality at WRRFs,” Tarallo said. “We wanted to demonstrate how to maximize resource recovery through harnessing the chemical, thermal, potential and kinetic energy contained in the treated wastes.”

Real-Life Statistics and Energy Flow Models Yield Valuable Information

The study included a detailed survey of approximately 40 WRRFs in North America and Australia, which yielded valuable statistics about energy use. In addition, nine industry leaders in net-zero energy wastewater treatment were selected from the 40 WRRFs for the development of case studies to document energy management lessons learned and best practices.

According to the WERF research, energy neutrality is within the grasp of water resource recovery facilities that use the conventional activated sludge process for biochemical oxygen demand (BOD) reduction (basic secondary treatment) and nitrification. But no two facilities are alike. In fact, the research team modeled the energy flows of 25 typical WRRF configurations, ranging from basic secondary treatment to membrane bioreactors for nutrient removal and water reuse. Facility operators can use these model results to find a configuration that is similar to their plant.

The research team also investigated the energy efficiency and energy recovery performance of 18 emerging technologies and processes in a variety of treatment plant configurations. The team used combinations of best-practice and these pioneering ideas to develop 10 hypothetical model facilities that approach or exceed energy neutrality.

Best in Class of Modeled Facilities

The best overall performance was observed for a plant that consisted of chemically enhanced primary treatment (CEPT) followed by BOD-only activated sludge treatment, then anaerobic digestion, including thermal hydrolysis pre-treatment of feed sludge and co-digestion of market-available fats, oils and grease (FOG) and food waste, and combined heat and power (CHP). That facility reached an energy rating of 139 percent, meaning it met its actual energy usage plus nearly 40 percent more.

The team also developed criteria to assess the triple-bottom-line (social, environmental and financial) sustainability score of six different biosolids management options. The results showed that anaerobic digestion with co-digestion, as well as CHP followed by land-application of biosolids, had the best overall sustainability score.

For minimizing energy use, the study showed that best practices include:

- The use of clean and properly maintained fine-bubble diffusers;

- Use of high-efficiency motors and generators operating near their design point;

- Maximization of solids capture in sludge processing;

- Maximization of primary sludge capture efficiencies;

- Co-digestion of fats, oil and grease/food waste in anaerobic digesters;

- Use of anoxic zones for energy recovery in nitrification plants.

The research on energy savings showed that improving primary treatment and solids capture in thickening and dewatering processes had the most significant total positive impact of all the best practices modeled.

“We found that the full combination of best practices reduces net energy use by roughly 40 percent compared to typical performance,” Tarallo said. “This is significant and demonstrates that proven technologies already exist for WRRFs to make a significant dent in their energy use.”

A Lofty but Reachable Goal

Tarallo said net-zero energy is a lofty goal that requires detailed planning and sustained commitment.

“The main challenges are different for each utility,” Tarallo said. “I would characterize the main challenge for biological nutrient removal (BNR) and membrane bioreactor (MBR) facilities as being technical – the technologies are just not sufficiently advanced at this time to confidently achieve the goal. For conventional and nitrification WRRFs, where technologies are available and well-proven, the challenges are more organizational and financial in nature.”

He said the overriding driver for success in all cases is strong leadership – a champion for the cause.

“We had the pleasure to speak with a variety of energy management champions about their utilities’ challenges and accomplishments. The passion that all of these leaders possess is infectious.”

This article was first published in Black & Veatch’s Solutions Online and is reprinted with permission.

Date posted: 23 February 2016

Posted in:

Biogas Systems, Tensile Fabrications

Date posted: 16 April 2015

Posted in:

Tensile Fabrications, Tension Structures

Four of us recently donned our penguin suits for a lavish charity bash at the splendid Tortworth Court Four Pillars Hotel in Wotton-under-Edge, organised by Nomenca Ltd as part of their committed fundraising work for WaterAid. The evening was an overwhelming success with fine dining, good company, interesting conversation and excellent networking opportunities.

Four of us recently donned our penguin suits for a lavish charity bash at the splendid Tortworth Court Four Pillars Hotel in Wotton-under-Edge, organised by Nomenca Ltd as part of their committed fundraising work for WaterAid. The evening was an overwhelming success with fine dining, good company, interesting conversation and excellent networking opportunities.

Of far greater importance, however, were the many thousands of pounds raised for a very worthy cause: delivering safe water, sanitation and hygiene projects in twenty-six countries around the world. Thanks once again to Nomenca for the invitation and to Tortworth Court for hosting the event.

For further details of WaterAid’s remarkable achievements please visit www.wateraid.org .

Four of us recently donned our penguin suits for a lavish charity bash at the splendid Tortworth Court Four Pillars Hotel in Wotton-under-Edge, organised by Nomenca Ltd as part of their committed fundraising work for WaterAid. The evening was an overwhelming success with fine dining, good company, interesting conversation and excellent networking opportunities.

Four of us recently donned our penguin suits for a lavish charity bash at the splendid Tortworth Court Four Pillars Hotel in Wotton-under-Edge, organised by Nomenca Ltd as part of their committed fundraising work for WaterAid. The evening was an overwhelming success with fine dining, good company, interesting conversation and excellent networking opportunities.