Date posted: 30 November 2017

Posted in:

Uncategorized

It seems like only yesterday when spring had sprung and we were called in to deflate the Coolhurst dome ready for summer. Time flies like an arrow though and winter is almost upon us, so it’s that time of year again to give comfort and protection to the hardy cold-weather players. This time the dome is covering two of the club’s new clay courts rather than the hard surfaces of previous years.

Date posted: 10 November 2017

Posted in:

Uncategorized

This aerial view of Cardiff Docks takes in three structures from two separate projects, designed and project managed by our Biogas team and fabricated by our Manufacturing arm.

The projects are two 2,000m3 slab-mounted BioSpheres for Dŵr Cymru Welsh Water at their Cardiff sludge treatment centre on the far left, and a 32m diameter anaerobic digester membrane BioSphere roof for the Cardiff Food Waste AD plant in the lower centre. We like to think that both of these successful projects enhance the Cardiff scene..!

Date posted: 1 November 2017

Posted in:

Uncategorized

91034-PM-COR-00002 – Testimonial

On a recent wastewater treatment plant digester lid replacement project, Eneraque utilised the membrane digester lids, fan blower assemblies and pipework supplied by AJ Tensile Fabrications.

AJ Tensile became the obvious choice of fabrication partner to deliver this project with for our gas holder needs early in the scoping stage of the project, providing competitive pricing, industry experience, helpful advice and backed up by a respected product.

I am happy to say that Richard, Raul, Rafael and the team at AJ Tensile satisfied our expectations, meeting their project commitments and delivering prompt service when we had installation or design queries surrounding the product. Eneraque have been able to proudly deliver, install and commission a ground-breaking Australian installation that the end client and builder have been impressed with, utilising AJ Tensile manufactured products.

Regards,

Noel Rosario

Project Manager

Date posted: 16 October 2017

Posted in:

Uncategorized

We have an immediate vacancy for an experienced industrial sewing machine operator/seamstress based in our production facility here in Caldicot. Hours are flexible to suit demand during a normal day shift, averaging approx 16 hrs per week.

Please email neil@ajtensile.co.uk detailing your experience and availability.

Date posted: 6 October 2017

Posted in:

Uncategorized

Our production facility is busy assembling a huge bespoke twin-skinned BioSphere gasholder for export to a client in the USA. Measuring 29 metres in diameter and with a height of 13 metres, this gasholder is one of the largest we’ve ever made a capacity of 5,500 cubic metres, and was assembled using high-frequency welding from 18 metre long panels of Type 3 reinforced Polyester/PVC membrane.

Date posted: 28 September 2017

Posted in:

Uncategorized

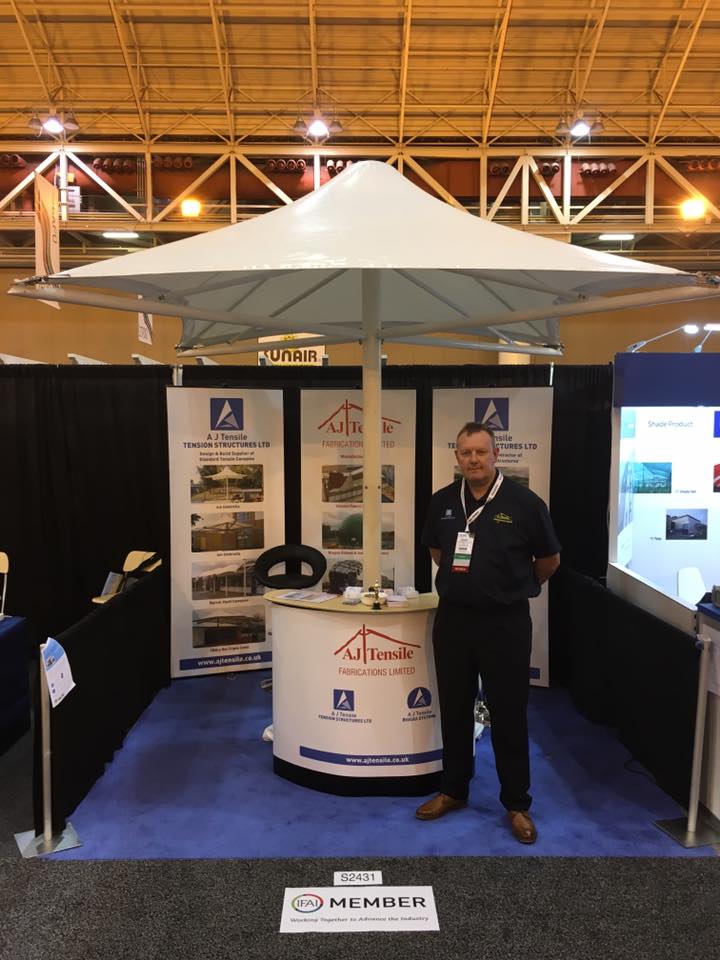

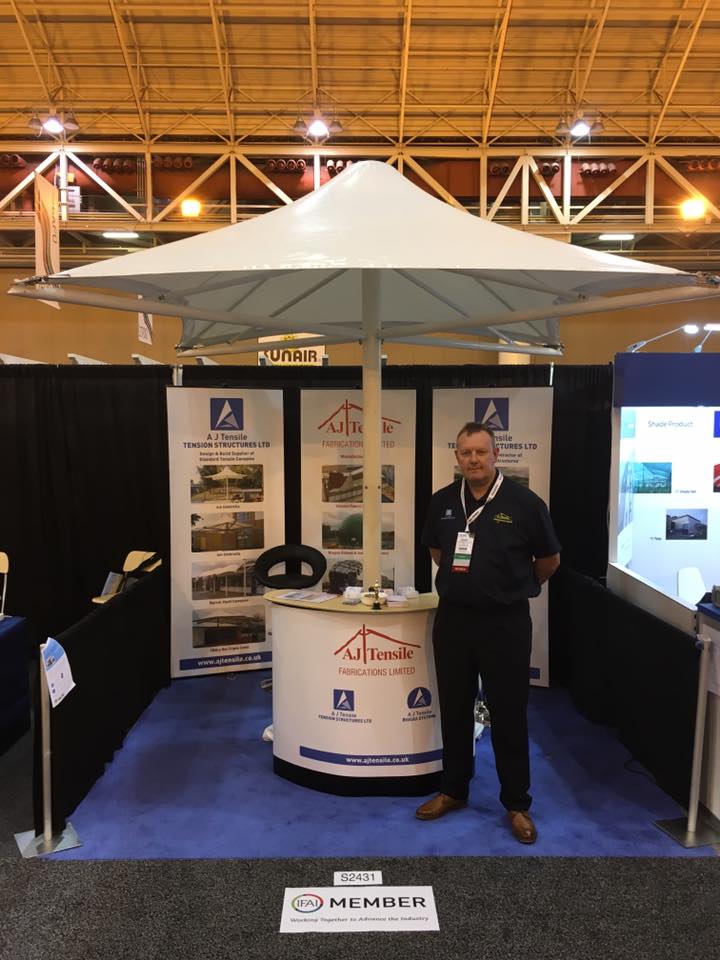

Two of our Group delegates Andrew Jerrum (Managing Director, Manufacturing) and Gary Patterson (Director, Structures) are currently exhibiting at the 2017 Industrial Fabrics Association International Expo in the USA. Come and meet them at booth number S2431 to discuss all of your tensile fabric requirements. The exhibition runs from 26th – 29th September at the Ernest N. Morial Convention Center in beautiful New Orleans.

https://ifaiexpo.com/

Date posted: 13 June 2017

Posted in:

Uncategorized

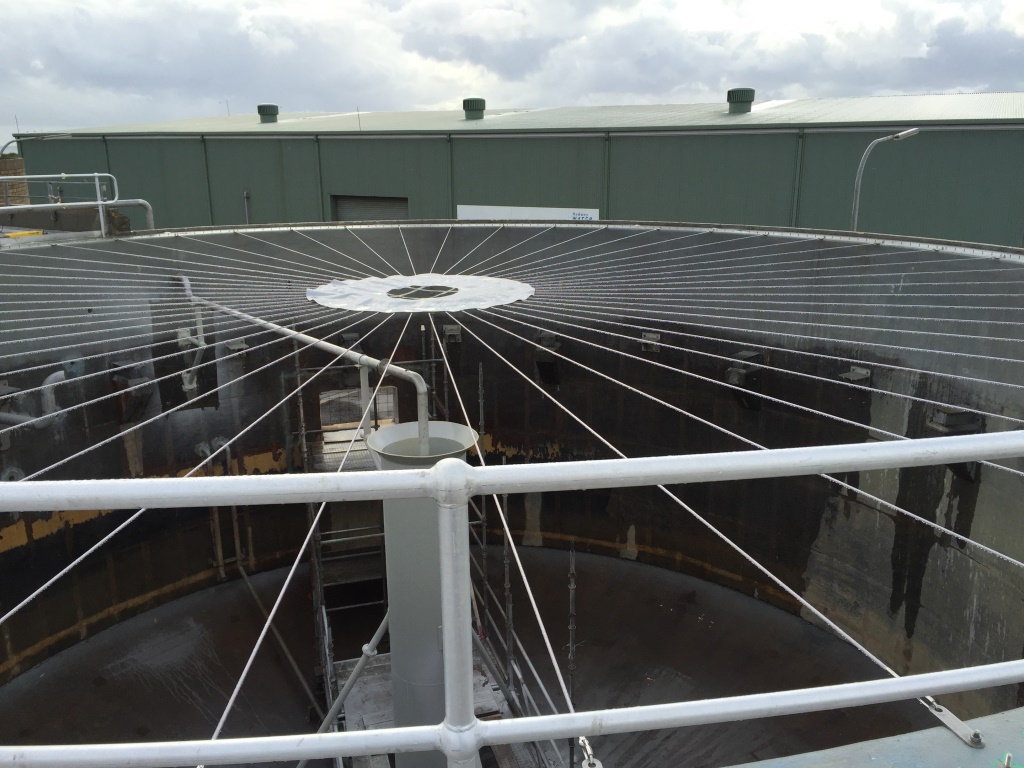

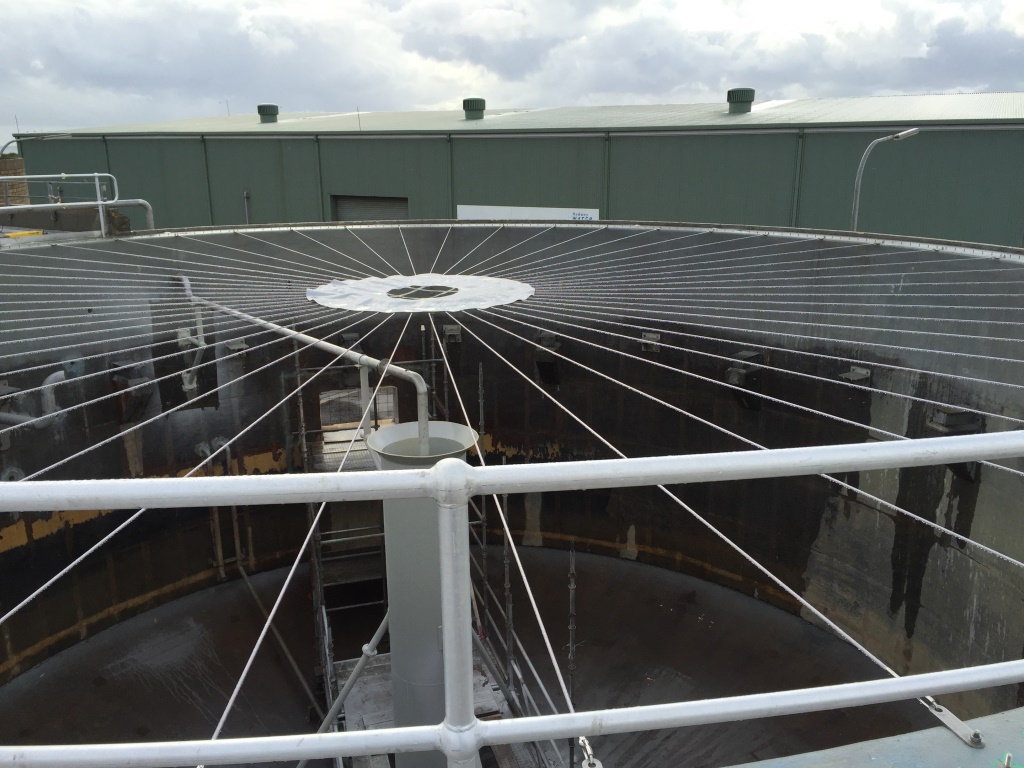

Our Biogas Systems division recently completed the design, manufacture and installation of two 15 metre diameter tank-mounted BioSphere membrane roofs, including bespoke membrane catcher systems.

The project was completed in close collaboration with our partners in Australia for the end client, Sydney Water. These BioSphere membrane roofs are of a unique design whereby the inner and outer membranes are joined by a special stainless steel component.

Date posted: 20 April 2017

Posted in:

Uncategorized

Mounted on top of a steel plinth, this small BioSphere gasholder was recently installed by our Biogas team at Kilmington, near Axminster in Devon for South West Water. Measuring 200 cubic metres when fully inflated, the dome was designed and manufactured at our production plant in Caldicot in close collaboration with our client Nomenca Ltd, with ductwork and piping manufactured by Grail Engineering to our design.

Date posted: 20 April 2017

Posted in:

Uncategorized

Our Biogas division recently completed a medium-sized gasholder for a South West Water plant at Hayle near St Erth in Cornwall. Measuring 570 cubic metres, the Polyester-reinforced PVC BioSphere gas dome was designed and manufactured at our production facility in Caldicot in close collaboration with our client, Tecker Ltd, and installed on top of an elevated concrete plinth. Ductwork was manufactured and supplied by Compass Ltd to our own design. For increased accuracy a laser level sensor was selected to monitor the storage volume rather than the alternative ultrasound sensor.